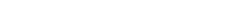

THHR-200

HOME

HOME- Food machinery

- Hot Air Blast

- THHR-200

본문

POWER

Three-phase four-wire system 380V 8kW/hr

HEATING SOURCE

Low Presure gas 210,000kcal/h

WORK CAPACITY

10kg~30kg/batch

WORKING TIME

6~10mins

-

-

The THHR-200 (industrial air roaster) gives your commercial grain factory the ability to roast up to 200kg/hour consistently while having full control of the roasting process. With nearly instant response to adjustments in temperature and airflow, this commercial air roaster has clear advantages over direct fire roasters. This roaster is designed to roast grains used for cereal products, grain foods, baby foods, tea materials, and pastes. The ability of the roaster to reach high temperatures allows for excellent puffing if desired.

Excellent Puffing Rate

The THHR-200 can puff grain quickly and evenly through high temperature operation. The puffing rate can be easily controlled based on the temperature, time, and airflow to account for differences in environmental conditions as well as the moisture content of what is being roasted.

Maximized Heat Efficiency

The design of the THHR-200 allows for maximum heating efficiency. Based on the material to be roasted the machine can be adjusted to provide consistent quality. Preheating the machine is also significantly faster than a direct fire roaster with preheating times of approximately 10 minutes.

Full Automation

Inputting → Roasting → Cooling → Discharging The entire roasting process can be automatically operated both to control for the desired quality and quantity. It’s simple to program the THHR-200 to meet multiple roasting applications.

MMI Simulation: Remote-Control System (Optional for Large Equipment)

Through the introduction of a remote-control system, work processes can be controlled from the comfort of your office. A touch screen control panel makes programing the roasts easy, and the data input/output management maximizes accuracy. For safety, the different functions of the machine are interlocked so if any part of the system receives an abnormal signal a warning and error message is generated.

SPECIFICATION